Early along, as a student of the Toyota Production System (TPS), now referred to as “Lean,” I struggled with some of the concepts and systems. For example, Shigeo Shingo’s claim that a four-hour machine setup could be reduced to less than ten minutes made me a skeptic.

“Perhaps,” I thought, “when Mr. Shingo talked about SMED, single minute exchange of dies, he was referring only to machinery in which the changeover involved die changes. CNC Lathes were different, I rationalized; no chance for single minute changeover there.”

I kept these doubts to myself although I believe the machine operators had similar doubts. We’d made modest setup improvements, but nothing like Shingo was suggesting. Anything beyond low-hanging fruit took us too far out of our comfort zone.

In 1996 however, when a consultant from TSSC, a division of Toyota, began working with us, it quickly became apparent to me through her questioning that our doubts arose from ‘conceptual blind spots’ developed through old setup practices. These were preventing us from seeing a multitude of improvement opportunities. With some priming from our consultant, we found waste in areas where, as Mr. Shingo would say, “it was thought not to exist.” Under the guidance of our TSSC consultant, our well-ingrained existing frameworks for analyzing problems were gradually un-learned as part of our Lean learning.

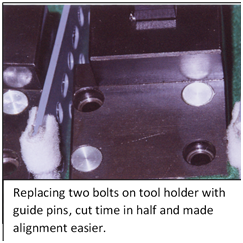

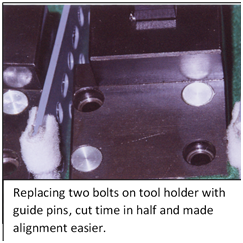

Our consultant, who had no special technical expertise with CNC equipment, nevertheless brought a conceptual framework to the table that turned our skepticism into science. She used a method I refer to as “directed discovery” constantly challenging us with questions about our beliefs and expectations. For example, we were asked, “Why are four bolts needed for the tool holders? After we got over the because-we’ve-always-done-it-that-way answers, one of the operators had a brainstorm: “Can we replace two of the bolts with guide pins?” he asked. We experimented with the idea and, notwithstanding the concerns of the CNC lathe manufacturer, the guide pin idea worked!

Our consultant, who had no special technical expertise with CNC equipment, nevertheless brought a conceptual framework to the table that turned our skepticism into science. She used a method I refer to as “directed discovery” constantly challenging us with questions about our beliefs and expectations. For example, we were asked, “Why are four bolts needed for the tool holders? After we got over the because-we’ve-always-done-it-that-way answers, one of the operators had a brainstorm: “Can we replace two of the bolts with guide pins?” he asked. We experimented with the idea and, notwithstanding the concerns of the CNC lathe manufacturer, the guide pin idea worked!

Over a four-month period, focusing on sixty-six parts that ran on one CNC lathe, setups were reduced first from an hour to thirty minutes, then twenty and finally to eight minutes for any changeover between any two parts. At that point the operators began measuring the setups in seconds.

The impact this had on our operation was truly revolutionary. An abstract understanding that we had gained from reading Shingo’s book was now replaced by a tacit learning that could only have come through guided discovery and continual practice: Learning by doing or, in this case, “Lean By Doing.”

There are two morals to this story:

- Book study or classroom activities alone cannot create deep learning and may, in fact cause persons to privately harbor doubts. Only with constant hands-on practice can we remove the conceptual blind spots that obscure the full benefit of Lean tools.

- The perspective gained through the mentoring from our consultant was necessary to help us see beyond our conceptual blind spots. Experienced eyes can guide inexperienced.

GBMP has chosen the “Lean-by-doing” theme for its 12th annual Northeast Lean Conference and in doing so we have invited some the most hands-on practitioners and experts to share their tacit learning with every participant. Over half of our sessions will be hands-on learning. The event gets under way in 26 days and registration is still open at www.northeastLEANconference.org. Hope to see you there.

O.L.D.

Our consultant, who had no special technical expertise with CNC equipment, nevertheless brought a conceptual framework to the table that turned our skepticism into science. She used a method I refer to as “directed discovery” constantly challenging us with questions about our beliefs and expectations. For example, we were asked, “Why are four bolts needed for the tool holders? After we got over the because-we’ve-always-done-it-that-way answers, one of the operators had a brainstorm: “Can we replace two of the bolts with guide pins?” he asked. We experimented with the idea and, notwithstanding the concerns of the CNC lathe manufacturer, the guide pin idea worked!

Our consultant, who had no special technical expertise with CNC equipment, nevertheless brought a conceptual framework to the table that turned our skepticism into science. She used a method I refer to as “directed discovery” constantly challenging us with questions about our beliefs and expectations. For example, we were asked, “Why are four bolts needed for the tool holders? After we got over the because-we’ve-always-done-it-that-way answers, one of the operators had a brainstorm: “Can we replace two of the bolts with guide pins?” he asked. We experimented with the idea and, notwithstanding the concerns of the CNC lathe manufacturer, the guide pin idea worked!