A Blog About Understanding The Toyota Production System and Gaining Its Full Benefits, brought to you by "The Toast Guy"

Peripheral Discoveries

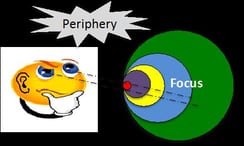

The following post is inspired by The Teachings of Don Juan, an anthropological novel from the 1960’s written by Carlos Castaneda chronicling his travels with Don Juan, a Yaqui shaman. To crudely paraphrase, according to Don Juan, the road to knowledge is blocked first by fear of learning new ideas, an experience most of us have had to one degree or another on our Lean journeys. For those who forge ahead in the face of this “natural enemy” of knowledge, we are rewarded with “clarity,” a confidence we gradually acquire as we seek to learn. Clarity, however, becomes the second enemy of knowledge, because its focus blinds us to new learning beyond a confined framework. Shingo called it complacency. I call it “too happy too soon.” The point is when we are too confident with our understanding of continuous improvement, new learning stops. With that preface, here is a story:

Sometimes we go to the floor with a specific intention, but along the way discover an opportunity well beyond the margins of our conscious attention. As an example, I was once tasked with improving the productivity of a high-speed manual packaging line about thirty feet in length, one where products were delivered by conveyor to a team of employees who frantically picked, packed and heat-sealed individual products in plastic sleeves. Picture Lucy and Ethel in the chocolate factory; that was the pace and tenor of this line. I was working with a team of six persons from production, each focused on a particular function within the line, while I stood back attempting to see the whole. There were a hundred observable reasons why this line did not hit packing targets, but that focus is not the subject of this blog post; only the backdrop.

Sometimes we go to the floor with a specific intention, but along the way discover an opportunity well beyond the margins of our conscious attention. As an example, I was once tasked with improving the productivity of a high-speed manual packaging line about thirty feet in length, one where products were delivered by conveyor to a team of employees who frantically picked, packed and heat-sealed individual products in plastic sleeves. Picture Lucy and Ethel in the chocolate factory; that was the pace and tenor of this line. I was working with a team of six persons from production, each focused on a particular function within the line, while I stood back attempting to see the whole. There were a hundred observable reasons why this line did not hit packing targets, but that focus is not the subject of this blog post; only the backdrop.

As I concentrated on the packing line, an area chosen by the company’s owner for improvement, an interference blip appeared just at the edge of my peripheral vision. Someone was observing from distance. A middle-aged employee standing in the finished goods warehouse was watching intently. Call him Jim; he was the warehouse manager. I briefly glanced in Jim’s direction and smiled. He smiled back and then during a break approached me. “I don’t know why you’re focusing on this line,” Jim said alluding to the packing line in front of me. “They’re producing far more than we sell. I can hardly find a place to put the products.”

“Where should we be watching?”, I asked Jim. “Come watch us pick and pack orders for Wal-Mart,” Jim replied. “We can’t hit their deliveries and are in danger of losing that business. If that happens, you won’t have to spend time on that packing line. It will be shut down!” At the end of the day, Jim and I reconvened in the warehouse for a quick review of the pick and pack process. His team was working overtime to complete an order that, if not shipped on-time in-full, might be refused altogether. As we walked the process, once again my peripheral vision picked up some blips. Other warehouse employees watching and listening just out of my line of sight were now keyed into our observation. They too had ideas about improvement to the shipping process. Ultimately, we re-focused our attention away from a packaging process that surely could be improved but was less critical to one that had only been on the periphery but nevertheless was extremely important.

Today I am frequently asked by organizations that I visit, “Where do you look for improvement when you visit a site?” My answer is, I try not to focus right away in order to receive any signal, direct or deflected. I don’t want to ‘point the camera’ based only on my past experience. Or as Shingo put it “The best place to look for improvement is in an area where it is thought not to exist.”

Do you let your current knowledge obscure opportunities for new learning? Are your decisions ruled exclusively by “clarity” or are you following the ways of Don Juan? Let me hear from you.

O.L.D.

PS It's hard to believe but there are only 48 days until The 2016 Northeast L.E.A.N. Conference! Our 12th annual event features five tracks and includes presentations by Lean thought leaders, peer-to-peer discussions of critical best practices, experiential learning through hands-on exercises and exceptional bench-marking opportunities, all designed to help you take your Lean initiative to the next level.The practical learning format caters to all learning styles & levels of experience. From the front lines to the corner offices, there is something for everyone. Please join us on October 4-5, 2016 at the DCU Center in Worcester MA to learn how to help your organization act its way into Lean thinking. Read more about the event, view the agenda, read the abstracts and register here.