A Blog About Understanding The Toyota Production System and Gaining Its Full Benefits, brought to you by "The Toast Guy"

P-D Ratios

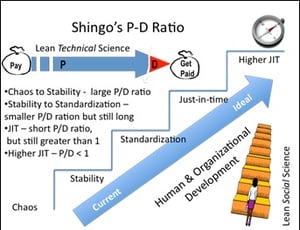

The last few weeks have been all things Shingo for me including a presentation at the Shingo Institute’s International Conference three weeks ago in Provo, Utah, followed by four days of Shingo Institute workshops at Vibco in Richmond, Rhode Island. Questions at both events about assessing for enterprise excellence caused me to reflect on a basic framework that Shingo himself used to explain the progression of what we refer to today as "Lean maturity".

The P-D Ratio was Shingo’s comparison of the time required to Produce a product to the time given by the customer to Deliver the product. A large P-D ratio, for example, was indicative of a producer who took much longer to produce a product than desired by the customer. In 1985, this was the condition in my business. We attempted to match the customer’s short “D” time by stockpiling inventory. Our push production method, as Dr. Shingo called it, was “speculative”, that is to say we built to forecast. Unfortunately our forecasts were wrong much of the time and there was an abundance of Muda in our production system. The atmosphere in the plant was one of frenetic expediting, particularly at month and quarter end. I don’t recall using the word “culture” at the time, but in today’s terms we did not yet have a culture of improvement. Shortly after I took a job as materials manager, a question posed to me by a buyer from one of our largest customers, a compressor manufacturer, summed up our P-D ratio:

The P-D Ratio was Shingo’s comparison of the time required to Produce a product to the time given by the customer to Deliver the product. A large P-D ratio, for example, was indicative of a producer who took much longer to produce a product than desired by the customer. In 1985, this was the condition in my business. We attempted to match the customer’s short “D” time by stockpiling inventory. Our push production method, as Dr. Shingo called it, was “speculative”, that is to say we built to forecast. Unfortunately our forecasts were wrong much of the time and there was an abundance of Muda in our production system. The atmosphere in the plant was one of frenetic expediting, particularly at month and quarter end. I don’t recall using the word “culture” at the time, but in today’s terms we did not yet have a culture of improvement. Shortly after I took a job as materials manager, a question posed to me by a buyer from one of our largest customers, a compressor manufacturer, summed up our P-D ratio:

“Welcome to your new job, Mr. Hamilton. Can you explain to me why your company takes sixteen weeks to fill an order for a product the size of my fist, while my company can make a product as big as a house and deliver it in a week?”

That mortifying question may very well have been the trigger for my first study of TPS. A read of Robert Hall’s Zero Inventories (1982) led via a footnote to Shigeo Shingo’s Study of the Toyota Production System (1981) and this is where the epiphanies began. The book was such a bad translation from the Japanese that it has become a collector’s item. (It was retranslated in 1989 to a more readable but less authentic form.) Using Shingo’s ideas, we began to shift our production from “speculative" to "authorized” - Mr. Shingo’s words to describe the shift from push production to pull. And little by little, the sixteen weeks reduced to ten and then five and eventually, over a period of years, to two weeks for our customer’s product. With starts and stops and lot of TPS learning opportunities, by 1990 we’d reduced the P-D ratio from 16:1 to 2:1, not exactly just-in-time, but improved enough to be recognized in 1990 by the Shingo Prize for Manufacturing Excellence.

By the fall of that year we were asked to tell our TPS story at the annual AME conference in Boston. A team of seven persons from my company each told a piece of the story: what we’d learned technically and how we worked together to overcome challenges and develop an improvement culture. After our presentation, each team member sat at a different lunch table, anxious to hear from other participants. As I seated myself for lunch, the gentleman to my right was already talking about some impressive results: shorter lead-times, inventory reductions, lower costs. Not to be outdone, someone across the table talked about same day delivery. Another told a story of enormous cost reductions. “These are really impressive results,” I thought to myself.

I broke my silence by announcing that while my company had worked very hard to improve, our results were not nearly so compelling as those described by others at the table. Hoping to capitalize on the experience of others at my table, I then asked, “What companies are you with?” To my complete surprise, everyone else at my table was a consultant. One was pushing Theory of Constraints, another was into TPM and a third was an MRP consultant. The rest were Lean consultants, a relatively new idea at that time. All had business cards in hand. Suddenly their improvement claims seemed a bit less credible. In 1985, there had been almost nothing written about TPS and the only Lean (TPS) consultants were from Japan. It was hard to find companies that had even heard of TPS. But, by the 1990 AME conference, Lean consultants were apparently multiplying like lab rats. The group at my lunch table outnumbered the doers by 9 to 1, a ratio that was later borne out more generally by other of my team members. “Lean is good business for consultants,” I skeptically thought to myself, “but what about their customers.”

Revisiting Shingo and his ideas over the last few weeks at conferences and training, I’ve concocted a whimsical P-D ratio for us to keep an eye on: The ratio of Pundits to Doers. (Yes, I am now a Pundit too.) Today’s pundits have titles superior to consultant: Lean Expert, Lean Practice Expert, Sensei, Master Sensei, Black Belt, Guru and so on. Have a laugh - We’re even on Weird Al’s radar! My unscientific application of this Pundit-Doer ratio leads me to believe that while there are many more Doers now than in 1990 (the good news), the Pundit-Doer ratio is getting larger (the bad news.) There are more of us, both internal and external, than there are doers.

Revisiting Shingo and his ideas over the last few weeks at conferences and training, I’ve concocted a whimsical P-D ratio for us to keep an eye on: The ratio of Pundits to Doers. (Yes, I am now a Pundit too.) Today’s pundits have titles superior to consultant: Lean Expert, Lean Practice Expert, Sensei, Master Sensei, Black Belt, Guru and so on. Have a laugh - We’re even on Weird Al’s radar! My unscientific application of this Pundit-Doer ratio leads me to believe that while there are many more Doers now than in 1990 (the good news), the Pundit-Doer ratio is getting larger (the bad news.) There are more of us, both internal and external, than there are doers.

During a recent discussion with my board of directors, the question was posed: “What do we want GBMP to look like in ten years?” One astute board member commented, “Perhaps we should ask ‘What do we want our customers to look like in ten years?’”

Where is your company on Shingo’s P-D scale? Where do you want to be in ten years? Please share a thought.

O.L.D.

Hey! Speaking of Shingo, there’s still time to register for our next Shingo Institute Discover Excellence Course, June 9-10 at Smith-Midland in Midland, Virginia. You can register here.

Also, this week is the last call for the early bird registration discount for our 11th Annual Northeast L.E.A.N. Conference on September 29-30, 2015 in Springfield MA - a great event to meet, hear from and share with other "doers" just like you. Read more and register here.

Finally, I hope you'll join me for my next "Tea Time with The Toast Dude" webinar on June 2. It's FREE! I'll be discussing Overcoming Organization Obstacles to Lean. Get the scoop here.