A Blog About Understanding The Toyota Production System and Gaining Its Full Benefits, brought to you by "The Toast Guy"

Permutations

For many years I worked for a manufacturer of pressure and temperature switches, a small company with a very big product selection. In our product catalog there were roughly three-dozen distinct product families with hundreds of standard products, each available with thousands of optional configurations. The average order quantity per line was two pieces. In short, we were what is commonly referred to today as a “low volume, high mix” manufacturer. The potential product selection was astronomical, perhaps in the hundreds of millions.

For many years I worked for a manufacturer of pressure and temperature switches, a small company with a very big product selection. In our product catalog there were roughly three-dozen distinct product families with hundreds of standard products, each available with thousands of optional configurations. The average order quantity per line was two pieces. In short, we were what is commonly referred to today as a “low volume, high mix” manufacturer. The potential product selection was astronomical, perhaps in the hundreds of millions.

I experienced this complexity first in 1971 while working in the marketing department of that company. My job in marketing was to present these innumerable specifications and styles in a manner that made ordering products easy for our customers. I had no idea, however, how many parts were needed to produce even a single product, let alone the hundreds of millions of permutations.

Component parts and raw materials, bills of material and production routings compounded that complexity in ways I did not even try to understand while I worked in marketing. But in 1977, when my job changed from marketing to IT, the picture changed. Every product I realized had parts, and many parts were parents to other parts. The relationships defined not only the products I’d sold while in marketing, but also the parts that comprised them and the location and sequence of production. The actual production floor at that time was a half-mile away from the computer room in another building so my understanding of those additional permutations and combinations was limited to what I saw in data volumes, flow charts and reports.

In 1984, after a moderately unsuccessful attempt to implement MRP, my company fired the materials manager. Somebody had to be accountable. And this is when I backed into a job I would never have dreamt of taking in 1971. I was offered the materials manager position. Armed with combined experience in marketing and IT, including an understanding of the mechanics of MRP, I headed to work nearer to the factory. Once more the permutations grew, this time jumping from the printed page and data file to actual stocking locations for raw material, components, assemblies and products. Notwithstanding MRP’s elegant computer simulations, it seemed we always had too much material that we didn’t need and not enough of what we did need. All of the work that I and others had done to implement MRP seemed be without effect. My customer – production -- was dissatisfied with material availability, and their customer was unhappy with our delivery performance.

About eighteen months after modest success in cleaning up the then speculative push production system work, I moved from managing materials to managing production as well; now in the factory and one step closer to the customer. The complexity problem I now saw was at a whole new level. All of the process and system problems that I could gloss over in my earlier jobs now became painfully obvious. That pain was the birth of TPS in our plant.

Over the next two years, we experimented with the concepts of TPS, in particular Kanban, which cut through complex permutations by focusing on many 1:1 relationships between consumer and provider, enabling us to attack our biggest problem: too much of one thing and not enough of something else. The momentous change in thinking was not without some short-term calamities (stories for other posts), but by 1990 our turnaround in customer service and productivity was sufficiently noteworthy to gain recognition by the Shingo Prize. I might have fooled myself at the time into thinking that we had mastered the permutations problem.

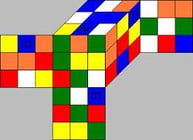

In 1994 however we undertook a project to move from small batch to 1x1 production for our most complex product line; one that represented a third of our revenues. My experience from marketing informed me that there were perhaps 25,000 distinct end items and a thousand times as many permutations. Pondering how we would manage this complexity one product at a time felt to me like solving a Rubik's Cube. But using the wondrous technology of computer programming, I was able to set up a Monte Carlo analysis to determine the probability of any particular set of permutations. There was a 90% chance that there would be 2500 different base assembly permutations in any one year! This is what I learned from experience in marketing, IT and materials management. I took my discovery to Jose L., the team leader for the pilot line that would move to one-piece flow.

“Jose,” I said, “I’ve looked at our sales history and analyzed our bills of material and assembly routings, and I’m stumped at how to layout the line for 2500 different combinations.

Jose looked at me for a moment and, trying to be respectful, replied to me, “There are only 16.”

“Sixteen what?” I asked.

“Sixteen combinations,” he replied with certainty. “We can build everything from sixteen base assemblies.”

And he showed me how.

O.L.D.

BTW: I’ll be teaching the Shingo Institute DISCOVER Excellence Course, May 5 and 6, at the 26th Annual Shingo Institute International Conference in Sandusky, Ohio. Hope to see you there

And: My next FREE webinar, “Tea Time with the Toast Dude”, entitled “Going to See” will offer some do’s and don’t's for managers who are wondering what to do when they “go to the Gemba.” Hope you can make it on Tuesday, May 20th from 3:00 -3:45 p.m EST. (Read more and pre-register here.)