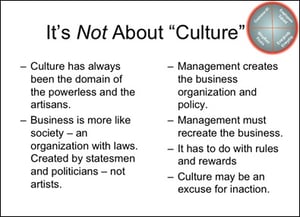

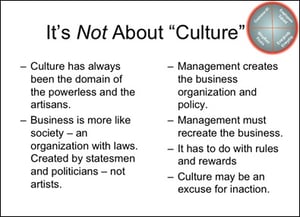

Some time ago, while giving a presentation entitled Organizational Obstacles to Lean, I displayed a slide with the title “It’s Not about Culture”. My point was that ‘culture’ is a bad analogy because it places the burden for change on the shoulders of employees rather than on management where it belongs.

Some time ago, while giving a presentation entitled Organizational Obstacles to Lean, I displayed a slide with the title “It’s Not about Culture”. My point was that ‘culture’ is a bad analogy because it places the burden for change on the shoulders of employees rather than on management where it belongs.

Later I drew criticism from a fellow presenter, a manager from a well-known leading edge Lean manufacturer. “I liked everything about your presentation,” he said after I finished, “except the part about culture. If the culture in our company had not changed we would never been able to sustain our gains.”

“It’s just the word,” I explained. “I think it’s often used to deflect responsibility away from bad management. I prefer the words “favorable environment” because they connote management responsibility."

My friend persisted that his Lean culture was embedded, so we agreed to disagree. A short time later, my friend’s company was acquired by a competitor. The ‘embedded culture’ disappeared in a few short months. Lean leaders from that company became lean refugees; some were fired, others departed voluntarily. What had taken years to build was unwittingly dismantled by a new management team, who apparently also felt the culture was embedded, and needed no further care and feeding.

On the flip side, John Shook, tells a great story about NUMMI, an early collaboration between Toyota and General Motors: In one short year, under a new management team from Toyota, the NUMMI plant – previously the worst GM plant in the US – became General Motor’s best assembly plant. Once again new management apparently triumphed over embedded culture, this time for the better. Was a new embedded culture created? I think not. Management had created an environment that favored continuous improvement.

Some persons may feel like I’m mincing words, but I think words direct our thinking and our actions; and buzzwords can cause us to turn a blind eye to real problems. When we define our business problem as “culture”, we may be only fueling a burgeoning market for ‘culture consultants” while avoiding the need for management to change bad systems and management practices.

How do you feel about culture? Please chime in. I’d like to hear from you.

O.L.D.

June 21, 2013

BTW Beginning in July, I’m going to experiment with a series of forty minute webinars I’ll refer to as “Tuesday Tea Time with The Toast Dude"; same themes as my blog, just a different medium where ideas can be exchanged in real-time. Added bonus: participants will be entered to win a free registration to our Northeast Region Shingo Conference, on September 24th & 25th in Hyannis, Massachusetts. The winner will be announced live at the conclusion of the webinar. I’ll provide more details about our first topic and how to register next week, but for now please "save the date" on your calendar for 3:00 p.m. on Tuesday, July 9.