When my son, Ben, was seven years old, he took his first guitar lesson. After the lesson, I was curious to know how liked the experience. He exclaimed, “Dad, the teacher said I only have to practice on the day of the lesson!”

When my son, Ben, was seven years old, he took his first guitar lesson. After the lesson, I was curious to know how liked the experience. He exclaimed, “Dad, the teacher said I only have to practice on the day of the lesson!”

“Hmm,” I replied, “are you sure that’s what he said?” Ben just gave me a sheepish smile.

I think everyone wishes learning was that easy, and we often behave as if it were. Both managers and employees are stingy with their time when it comes to understanding and practicing lean. They opt for books on tape, one hour webinars, DVD’s (like GBMP’s) and lunch-and-learns which may get them started in a good direction, but are not enough. Like my seven-year-old son, they expect that practicing once in a while is good enough, that somehow we can learn by cramming.

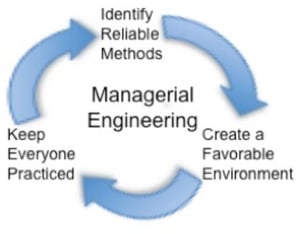

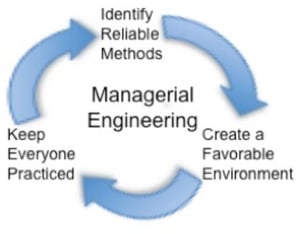

The reality is that notwithstanding the occasional epiphany, we learn in a continuum, forging our understanding in bits and pieces through trial and error. GBMP’s slogan, “Everybody Everyday”, is as much a recognition of that learning model as it is our expression of what we believe is meant by “Kaizen.” In fact, Kaizen and learning both must be continuous - not sporadic and batchy. Deming Prize winner Ryuji Fukuda describes this learning cycle with three basic requirements (shown above): Managerial Engineering

- Identify Reliable Methods – in other words identify the behaviors and practices of the most successful companies, and emulate these.

- Create A Favorable Environment. Management’s job is to create an environment in which employees are valued for their creative abilities and are rewarded for surfacing problems and improvement opportunities -- a very large topic for later posts.

- Keep Everyone Practiced. This is the “Everybody Everyday” part. For my son, Ben, that meant picking up the guitar and practicing every day, not just on lesson day. More generally it means “learning by doing” in the actual workplace every day. Too many organizations skip this step opting instead for a “Somebody Sometimes” approach commonly called the “event.” What employees learn from this approach is that improvement is only for some persons and it’s apart from rather than a part of the workday.

Fukuda’s book, Managerial Engineering (1983) was the very first Lean book published by Norm Bodek, and I think one of the best ever from Productivity Press. Ironically, it now appears to be out of print (but available for a penny plus shipping costs at resellers.) For over 25 years I’ve alluded to Dr. Fukuda’s model with the promise to clients, “If you follow the three steps, you will succeed,” but also warning, “the steps are not easy – and the third step is the most difficult.” More recently, Mike Rother’s insightful book, Toyota Kata, adds more weight to this everybody everyday learning model. Mike will be speaking at the Northeast Shingo Conferencein Springfield, Mass in October. (There’s still time to get early bird pricing before May 1.)

What my son, Ben, realized at the age of seven, is the key point of this post. But there’s a critical second part to this thinking that will be in my next post. In the meantime please share your lean learning experiences.

O.L.D.